About Us

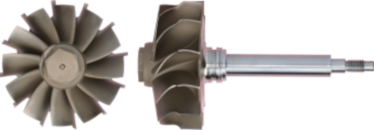

The LeadTurbo team offers global reverse-engineering support for turbocharger parts remanufacturers, providing high-quality, compatible replacement components you can rely on.

LeadTurbo: Our Reverse-Engineering Process for High-Quality Turbocharger Parts.

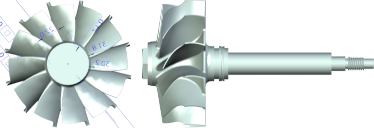

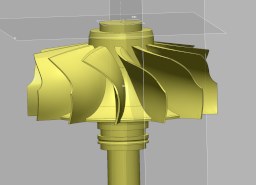

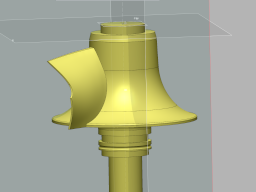

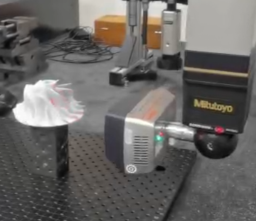

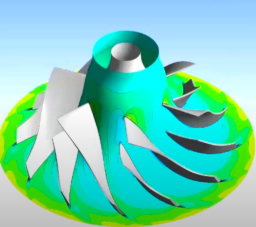

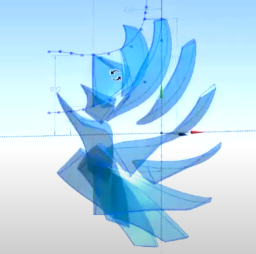

Under the extraordinary precision of our Mitutoyo laser measurement system, we generate massive point clouds—on the scale of hundreds of millions of data points—achieving measurement error as low as 0.01 mm or even finer. These finely detailed datasets empower us to trace every nuanced contour and curvature with near-perfect accuracy. From this rich foundation, we reconstruct ultra-faithful 3D meshes that mirror the real object in uncanny detail, delivering models so precise they leave no room for speculation.

Under the extraordinary precision of our Mitutoyo laser measurement system, we generate massive point clouds—on the scale of hundreds of millions of data points—achieving measurement error as low as 0.01 mm or even finer. These finely detailed datasets empower us to trace every nuanced contour and curvature with near-perfect accuracy. From this rich foundation, we reconstruct ultra-faithful 3D meshes that mirror the real object in uncanny detail, delivering models so precise they leave no room for speculation.

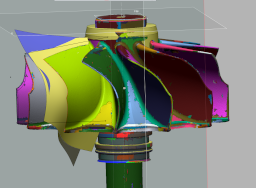

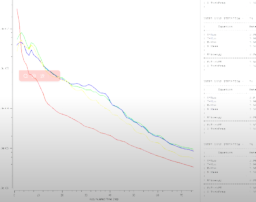

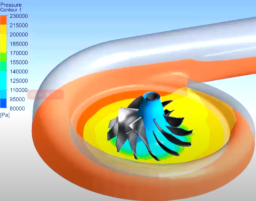

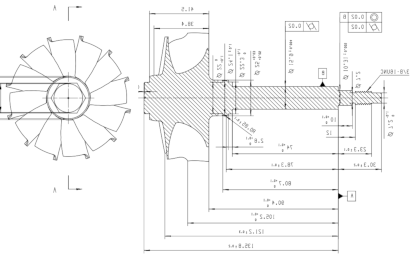

Backed by high-fidelity FEA simulations, our team probes every possible scenario—from extreme stress and wear to tight-tolerance fits and thermal cycling—so you don’t have to. We catch problems long before prototyping, shorten development cycles, lower production costs, and ensure products hit the market with proven reliability. The final CAD drawings are not just accurate; they’re ready for smooth tooling, assembly, and certification.

Backed by high-fidelity FEA simulations, our team probes every possible scenario—from extreme stress and wear to tight-tolerance fits and thermal cycling—so you don’t have to. We catch problems long before prototyping, shorten development cycles, lower production costs, and ensure products hit the market with proven reliability. The final CAD drawings are not just accurate; they’re ready for smooth tooling, assembly, and certification.

The outcome is clear: faster time-to-market, lower costs, and turbocharger parts you can trust.

How does LeadTurbo Guarantees Product Quality?

Prevent recurrence: Don’t generate the same problem—aim for root-cause correction and learning.

Mistake proofing & risk prevention: Implement DFMEA/PFMEA and proactive controls.

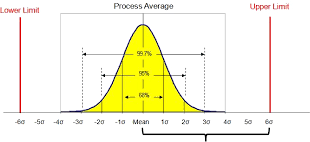

Six Sigma stands as the enduring cornerstone of quality management, embodying our unwavering commitment to excellence. At LeadTurbo, the DMAIC cycle serves as the driving force behind our continuous internal quality improvements, ensuring that every process is meticulously refined. Our dedication to achieving customer satisfaction is not just a promise—it is the foundation upon which we build lasting relationships and deliver exceptional value.

Six Sigma stands as the enduring cornerstone of quality management, embodying our unwavering commitment to excellence. At LeadTurbo, the DMAIC cycle serves as the driving force behind our continuous internal quality improvements, ensuring that every process is meticulously refined. Our dedication to achieving customer satisfaction is not just a promise—it is the foundation upon which we build lasting relationships and deliver exceptional value.