Advanced Cast Compressor Housings for Turbocharger Remanufacturing

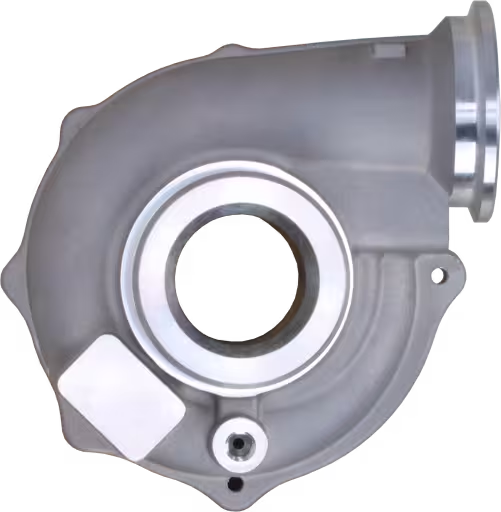

In turbocharger remanufacturing, the compressor housing is a critical component that must match OEM-quality geometry and precision. Achieving this level of quality requires cutting-edge casting and machining methods to produce parts that install easily and perform reliably like new.

Modern advanced casting processes replicate the thin-walled, complex shapes of original housings while avoiding defects like porosity and cold shuts. Optimized gating design and controlled pouring temperature ensure the molten alloy fills even intricate volute passages without voids or premature cooling. Careful use of chills and casting simulation, for example, can prevent shrinkage porosity where thick sections meet thin walls. Cold shut defects (incomplete seams from insufficient fusion of cooling metal) are likewise eliminated by maintaining proper metal fluidity. The result is a dense, high-integrity casting that faithfully reproduces every bolt hole, flange, and airflow contour of the OEM design.

After casting, each housing undergoes precision machining and a rigorous inspection workflow with dozens of steps. Critical mounting faces, seal grooves, and ports are CNC milled or turned to tight tolerances (around ±0.010″). All surfaces are then deburred and polished to remove imperfections and optimize airflow. Throughout machining, extensive quality checks occur at every stage, with roughly 30–40 distinct operations and inspections in total. Computerized measuring equipment (CMM) verifies all key dimensions, and each housing is pressure-tested for leaks to ensure no hidden porosity or micro-cracks compromise its integrity. Comprehensive quality programs subject every unit to over thirty checks and measurements, resulting in performance and reliability on par with a brand-new part. This meticulous approach yields a finished compressor housing that is dimensionally precise and ready for assembly.

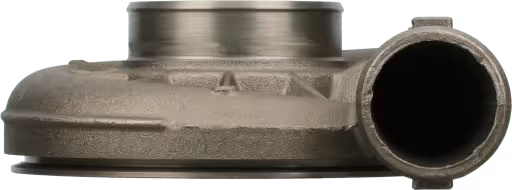

High-grade aluminum alloys are the standard choice for compressor housings due to their excellent strength-to-weight ratio and thermal conductivity. However, cast iron versions are offered for high-load applications that demand extra strength. Cast iron housings provide superior strength and hardness for heavy-duty use, making them suitable for large diesel engines or industrial compressors under extreme pressure. They withstand wear and deformation and inherently damp vibration due to their greater mass. Though cast iron is heavier and prone to rust (necessitating protective coatings), it gives remanufacturers a robust option when maximum durability is the priority. Both aluminum and cast iron housings undergo the same precise machining and finishing (e.g., shot blasting, coatings) to ensure smooth surfaces and corrosion protection for long service life. Our replacement housing is engineered to match the original dimensions for a seamless fit, while vastly improving the turbo’s heat resistance and longevity. This means a turbo rebuilt with our advanced housing can confidently endure higher exhaust temperatures and boost pressures without risk of failure. The result is a turbocharger that’s as solid and reliable as it was when brand new – if not more so.

Summary of Core Advantages

Key benefits of these advanced compressor housings for remanufacturers include high reliability, easy installation, lower rejection rates, and long service life. Premium materials and exacting processes produce housings that are extremely durable, matching OEM longevity. Their precise OEM fit means each housing installs quickly with no modifications, cutting labor time and virtually eliminating any fitment issues. Comprehensive inspection also leads to far fewer rejects or returns, so remanufacturers can trust each part to meet their standards on the first pass. Ultimately, the combination of advanced casting, precision machining, and strict quality control yields compressor housings that let remanufactured turbochargers deliver like-new performance with confidence. Comprehensive Machining Workflow: Over thirty meticulous steps ensure tight tolerances, uniform wall thickness, and superior surface finish in every housing.