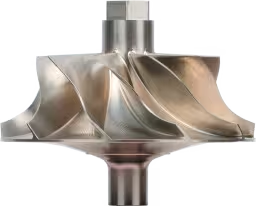

Experience the Difference with Our Compressor wheels

At the heart of every high-performing heavy-duty turbocharger lies the quality of its impeller. Turbocharger maintenance professionals know that for large engines in heavy trucks and construction machinery, the impeller’s material and build can make or break performance. Our impellers are crafted from premium alloys and produced with state-of-the-art manufacturing to meet the most demanding requirements. By combining advanced materials (like aluminum, stainless steel, and titanium) with precision fabrication techniques, we deliver impellers that enhance turbo responsiveness, durability, and efficiency for heavy-duty applications.

Premium Materials for Heavy-Duty Performance

We offer impellers in three superior materials—each chosen for its proven performance in heavy-duty turbochargers:

Aluminum Alloy: Ideal for compressor wheels, aluminum alloys are lightweight and reduce rotating mass. This low density means less inertia, so the turbo spools up faster and the engine responds more quickly to throttle changes. Aluminum impellers are perfect where quick boost and efficiency are needed, contributing to better fuel economy and reduced turbo lag in heavy vehicles.

Stainless Steel: Renowned for its strength and corrosion resistance, stainless steel impellers thrive in high-temperature, heavy-duty conditions. They can withstand the heat and stress of continuous operation, making them suitable for turbochargers on long-haul trucks and industrial machines. Even under extreme exhaust heat and pressure, stainless steel maintains its integrity, ensuring reliable boost and longevity.

Titanium Alloy: Titanium impellers marry exceptional strength with a superb strength-to-weight ratio. Titanium’s light weight (yet high tensile strength) allows for robust blades that handle extreme centrifugal forces without excess mass. This material offers outstanding durability and temperature resilience in both compressor and turbine wheel applications. In fact, many OEM heavy-duty turbochargers now use titanium wheels to endure the tremendous loads and impacts of daily use in trucks and equipment. The result is an impeller that resists heat, wear, and fatigue, even in the harshest operating environments.

By selecting the optimal material for the job, we ensure our impellers maintain their shape and strength under prolonged high-speed rotation, delivering consistent boost pressure mile after mile.

Precision Manufacturing: Casting vs. 5-Axis CNC

Choosing the right manufacturing technique is just as vital as choosing the right material. We utilize both precision casting and advanced 5-axis CNC machining to create impellers, giving you the best of both worlds:

High-Integrity Casting: Our casting process provides a solid foundational shape with uniform properties. Using modern methods (like low-pressure casting), we achieve smooth, defect-free blade surfaces and excellent base durability. Cast impellers are a cost-effective choice for volume production, offering consistent quality and robust performance as a starting point for heavy-duty turbo needs.

5-Axis CNC Machining: For unmatched precision and flexibility, we turn to 5-axis CNC machining. In a single setup, our machines can sculpt complex, aerodynamically optimized blade geometries with tight tolerances and high surface finish quality. This means we can produce intricate impeller designs that standard 3-axis machines or older methods simply can’t replicate. The 5-axis process also minimizes manual rework – the impeller comes off the machine nearly ready to perform. The result is a “billet” machined impeller with superior dimensional accuracy and balance. This technique is ideal for custom prototypes or small batches, since it reduces setup time and tooling costs compared to creating new casting molds. Whether you need one-off replacements for specialized machinery or a short production run, our 5-axis machining delivers quick turnaround without compromising quality.

Aerodynamic Blade Design & Efficiency

It’s not just about what an impeller is made of or how it’s made—it’s about how it’s designed to perform. That’s why our impellers feature aerodynamically refined blade curvatures and profiles engineered for optimal airflow. Each blade is shaped to minimize turbulence and evenly distribute stress, which reduces the chance of deformation or failure under load. Smooth, sweeping blade geometry guides air efficiently into the compressor housing, resulting in higher pressure ratios and lower losses. In practice, a well-designed impeller improves the turbo’s efficiency by reducing drag on the air and ensuring more air is compressed with each revolution. This means the engine can receive a denser charge of air, boosting horsepower and torque output without extra strain.

Critically, our refined designs also enhance structural reliability. By eliminating sharp stress risers and using thicker cross-sections only where needed, we create blades that can flex slightly without cracking, handling the intense centrifugal forces at high RPM. The impeller’s efficiency directly impacts the turbocharger’s ability to boost engine power, so our design improvements translate to tangible gains in engine performance and responsiveness. Even under extreme operating conditions, such as continuous high boost in a heavy truck pulling a load uphill, our impellers maintain stability and deliver consistent airflow. The combination of advanced CAD aerodynamic modeling and real-world testing has allowed us to optimize blade angles and curvature for peak performance and durability.

The Performance Advantage

By uniting premium materials, precision manufacturing, and aerodynamic design, our impellers give heavy-duty turbochargers a decisive performance edge. For turbo rebuilders and service professionals, the benefits are clear and immediate:

Faster Turbo Response & Smoother Airflow: Lighter, optimally shaped blades mean quicker spool-up and more stable airflow through the compressor. Reduced rotational inertia lets the turbocharger rev up rapidly, eliminating lag and delivering boost exactly when the engine needs it. Drivers of heavy trucks or machinery will notice improved throttle response — for instance, when accelerating a loaded dump truck or heavy hauler, the turbo “comes on” faster, providing power without hesitation. The smooth airflow also minimizes surge and ensures the engine breathes easily across the RPM range.

Exceptional Durability: Materials like titanium and stainless steel give our impellers outstanding resistance to heat, corrosion, and fatigue. In demanding environments (high EGTs, long duty cycles, dusty or corrosive conditions), these impellers stand up to the abuse and maintain their mechanical properties even at temperatures exceeding 1,000°C. That translates to a longer service life and fewer replacements. Turbocharger maintenance intervals can be extended because the impeller won’t be the weak link – it’s built to last as long as the rest of the turbo. Fleet operators and equipment owners gain confidence that their turbochargers will stay efficient and reliable over countless miles or hours of operation.

Engineered for Agility & Value: Our manufacturing approach provides flexibility and cost-effectiveness that benefit both small turbo shops and large rebuild centers. The 5-axis CNC process is perfect for rapid prototyping and custom impeller solutions – you can get a precisely machined impeller for a rare engine model or an experimental upgrade without the long lead time of casting. Small-batch runs become economically feasible, since we save on extensive tooling and setup costs by machining from billet. This agility means you can respond faster to your customers’ needs, reducing equipment downtime. Additionally, the consistency and balance of our billet impellers often exceed that of mass-produced cast wheels, leading to easier balancing of the turbo and potentially less wear on bearings. In short, you get a high-performance product with a quicker turnaround and excellent value, which you can confidently pass on to your clients.

By upgrading to our premium turbocharger impellers, turbocharger maintenance professionals can offer end-users a tangible boost in performance and reliability. Whether it’s keeping a fleet of heavy-duty trucks on the road or maximizing the uptime of construction equipment, our impellers make a noticeable difference. Experience the peace of mind and performance gains that come from components engineered for excellence in the most demanding conditions. Your turbocharger rebuilds and repairs will reach new levels of quality – and your customers will feel the results every time the boost kicks in.

Unlock the full potential of your heavy-duty turbochargers with impellers that truly stand out – engineered for power, built for endurance, and crafted for precision.