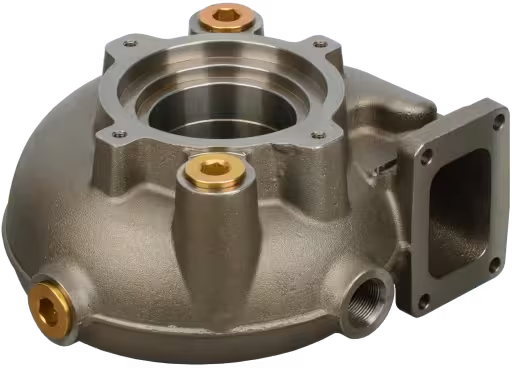

"Solid as a Fortress, Unyielding in Heat" – Silicon-Molybdenum Turbine Housing Crowns Performance

Our turbine housings are crafted from a specialized silicon‑molybdenum (Si‑Mo) nodular cast iron—a high‐temperature alloy designed to thrive under extreme heat and stand as solid as a fortress where ordinary cast irons fail. By incorporating approximately 4–5% silicon and 0.5–1.0% molybdenum into the iron, the alloy gains robust oxidation resistance and exceptional strength at high temperatures. The result is a turbine housing that operates safely and reliably at sustained exhaust gas temperatures up to 820 °C, and can even endure brief excursions beyond 850 °C without cracking or deforming.

Silicon in the mix promotes the formation of a protective oxide layer on the surface (preventing rust and scaling) and also raises the iron’s ferrite-to-austenite phase transformation threshold (A₁), meaning the metal’s structure remains stable at higher heat levels. Meanwhile, molybdenum fortifies the alloy’s internal structure by adding high-temperature tensile strength and creep resistance. Together, these elements ensure the housing stays strong and dimensionally stable amid aggressive exhaust heat cycling.

Every stage of our casting process is tightly controlled, from creating precise sand molds and cores to carefully pouring the molten Si‑Mo iron under strict temperature management. This ensures we can faithfully cast the intricate, thin-walled shapes and complex flow passages required in a modern turbine housing.

The result is castings free of common flaws like cold shuts, inclusions, or porosity that could weaken the part. By eliminating such defects, we achieve consistently high yield and excellent dimensional accuracy.

Next, shot blasting and polishing give the housing a clean, scale-free surface texture. Finally, every unit passes a rigorous inspection of all dimensions, wall-thickness uniformity, and surface finish, ensuring each turbine housing meets the highest standards of precision and durability demanded by advanced turbocharger systems.

In turbocharger rebuilds and upgrades, the turbine housing is often a critical component to replace. Stock cast iron housings from older units commonly develop cracks (especially around the wastegate) or suffer distortion after years of extreme heat cycles. Rather than reusing or attempting to weld a fatigued housing, swapping in our high-performance Si‑Mo ductile iron housing is a far better solution.

Our replacement housing is engineered to match the original dimensions for a seamless fit, while vastly improving the turbo’s heat resistance and longevity. This means a turbo rebuilt with our advanced housing can confidently endure higher exhaust temperatures and boost pressures without risk of failure. The result is a turbocharger that’s as solid and reliable as it was when brand new – if not more so.

Summary of Core Advantages

Material Excellence (Si-Mo Ductile Iron): Exceptional oxidation and thermal fatigue resistance, while maintaining high strength at sustained temperatures up to 820 °C (with brief peaks beyond 850 °C).

Advanced Casting Technique: Precise, defect-free fabrication of complex, thin-walled structures, ensuring high yield and faithful dimensional accuracy.

Comprehensive Machining Workflow: Over thirty meticulous steps ensure tight tolerances, uniform wall thickness, and superior surface finish in every housing.